Product description

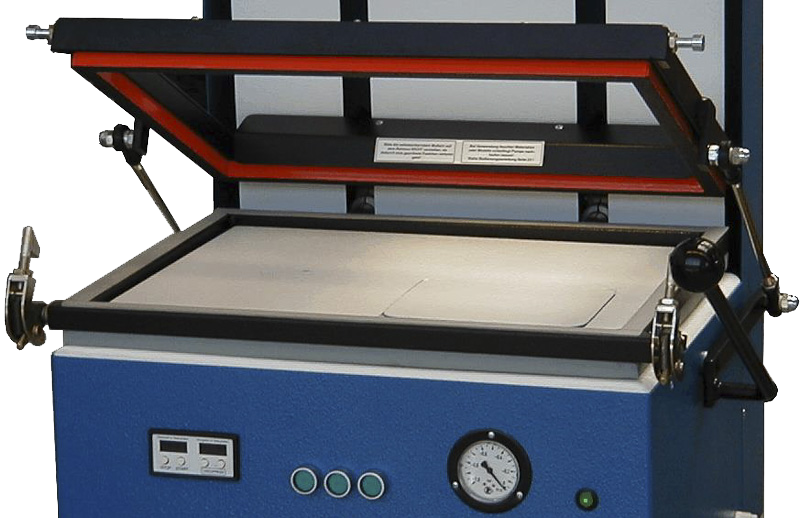

The VACUPRESS 620 S3 COOL-TEC is the latest version of the proven VACUPRESS 620 S3 thermoforming unit and has been specially developed for the requirements in orthopedic shoe technology as well as in the orthopedics and prosthetics sector. With the newly developed COOL-TEC cooling system, materials can now be automatically cooled directly on the device, reducing cooling time by up to 75%. This significantly increases the productivity of your workshop by shortening throughput times.

The patented UNILOCK material clamping system allows for quick and uncomplicated handling. The work frame can be opened and closed with just one hand, supported by a gas pressure spring. No adjustments for different material thicknesses are necessary, and disruptive levers or complicated locking mechanisms are eliminated.

The VACUPRESS 620 S3 UNILOCK molds all thermoplastic materials. The integrated vacuum control guarantees highest molding accuracy and efficient production. The powerful, maintenance-free vacuum pump with high reserve capacity ensures smooth operation. A fully integrated work surface illumination allows optimal control of the thermoforming process and ensures perfect results.

Technical Data: VACUPRESS 620 S3 COOL-TEC

- Article number:

- Type:

- Floor space:

- Dimensions:

- Electrical connection:

- Power consumption:

- Heating:

- Heating time:

- Vacuum pump:

- Dust filter:

- Frame dimensions:

- Frame guide:

- Vacuum chamber:

- Frame locking:

- UNILOCK mechanism:

- Activation grid:

- Lighting:

- Vacuum automation:

- Heating automation:

- COOL-TEC cooling system:

- Color: