Product description

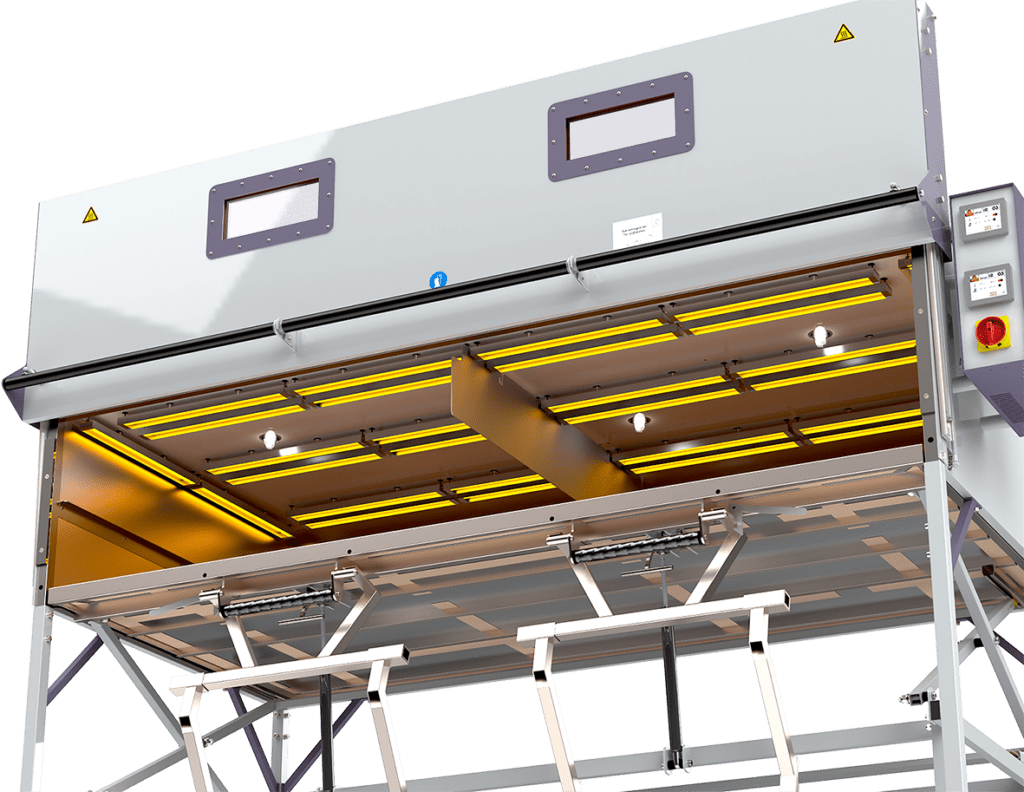

The Infrared Oven IR2103 DUAL was developed as an extension of the successful Witzel IR oven series, specifically designed for the requirements of larger models in orthopedic technology. With a heated surface of 2140 x 1040 mm, it enables the processing of plastic sheets for large models, such as seat shells, in one piece. The DUAL version offers the possibility to conduct two independent heating processes in parallel and simultaneously heat two plates up to a size of 1 x 1 m or two blister-forming frames. Thanks to the dual design of the thermostat control, materials with different temperatures can be processed simultaneously.

Like all Witzel infrared ovens, the IR2103 DUAL also features innovative optical temperature measurement and a control system of the latest generation. The newly developed control system of the ..03 series with a 3.5″ touch panel serves as the central operating unit of the oven. In addition to the simple input of the desired target temperature, the current actual temperature of the material is displayed on the main screen. From there, timer and ramp functions as well as the graphical display of the heating process are quickly accessible. A USB interface ensures the future-proofing of the control system through program updates.

Technical Data: Infrared Oven IR2103 DUAL

- Article number:

- Type:

- Floor space:

- External dimensions:

- Internal dimensions:

- Material cart:

- Electrical Connection:

- Heating:

- Temperature Measurement:

- Temperature controller:

- Door mechanism:

- Interior lighting:

- Color:

- Weight:

- Optional Accessories