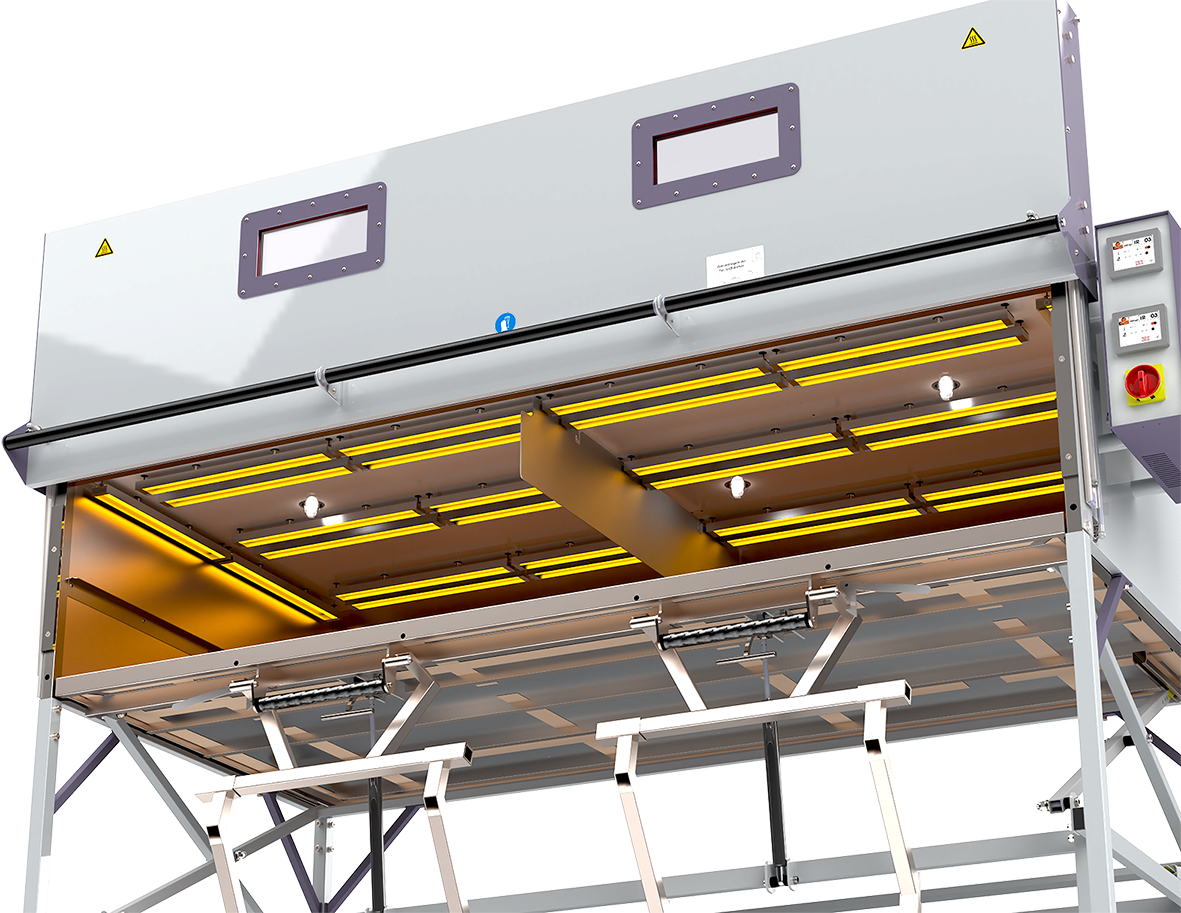

Heating Ovens

Energy-efficient ovens for thermoplastics and pre-preg composites.

Our ovens offer precise temperature control and reliable performance for a wide range of applications. Designed for maximum efficiency, they ensure optimal heat distribution and maximum energy savings.