Developed from practical experience, tried & tested over many years

Specialized solutions

Tailor-made service

Durable products

Over 40 Years of Expertise in Orthopedic Technology

Your success is our motivation - with precision, innovation and a clear focus on your needs, we have been a reliable partner for our customers and specialist retailers in orthopaedic and footwear technology for decades.

About usQuality - 100% Made in Essen

What are you looking for?

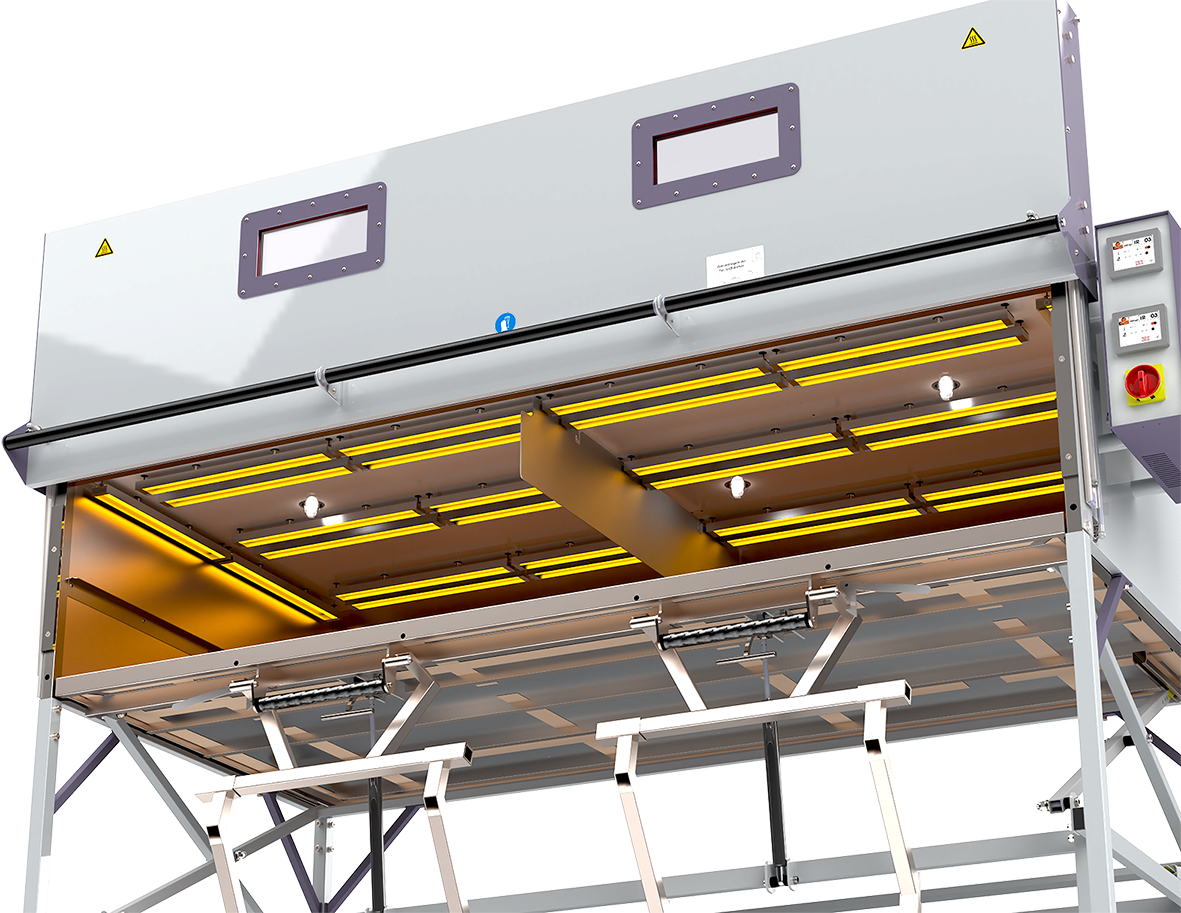

Heating ovens

Energy-efficient ovens for thermoplastics and pre-preg composites.

Vacuum thermoformers

Efficient Solutions for Insoles, Orthoses, Seating Shells, etc.

Your success is our motivation

At Witzel Vacupress, quality and service are our focus. With over 40 years of experience, we optimize your workshop processes through innovative technology and tailored support.